JANUARY 23, 2023 • By Matthew Tierney

In the 2023 fall term, the ECE department offered the first-ever electric vehicle (EV) systems course at the University of Toronto.

The multidisciplinary course discusses EV subsystems, with a core focus on energy modelling and efficiency. Titled ’Special Topics in Energy Systems: Electric Vehicle Systems & Energy Management’ (ECE1049), it aims to give graduate students a theoretical background on how power and energy flow through EVs, along with hands-on experience of their components. The students leave with a solid understanding of the concepts that are required to design high-performance EV systems.

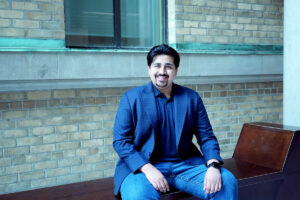

“The grad course was a pilot to explore how a hands-on EV course could fit into our curriculum,” says sessional lecturer Dr. Zhe Gong (ElecE 1T5, ECE MASc 1T8, ECE PhD 2T2). “We’re making sure that we understand the hardware requirements, that we can frame a meaningful scope of experiments, and that students can experience sufficient hands-on time through the lab sessions.”

One of the motivations for the course is to meet the industry demand for newly trained, EV-focused automotive engineers in this fast-growing electrification field.

According to the International Energy Agency, the number of EV models available on the market doubled from 2018 to 2022, to a total of 500. And the number of zero-emission vehicles (ZEVs) on the road is slated to increase dramatically in the next decade. Within Canada, this will be spurred in part by the federal government’s emissions reduction plan, which sets rising incremental sales mandates for new vehicle purchases — by 2035, 100% of light-duty vehicles sales must be ZEVs.

News about Stellantis-LGES and Volkswagon battery plants coming to Ontario highlights the need for engineers with EV technology skills.

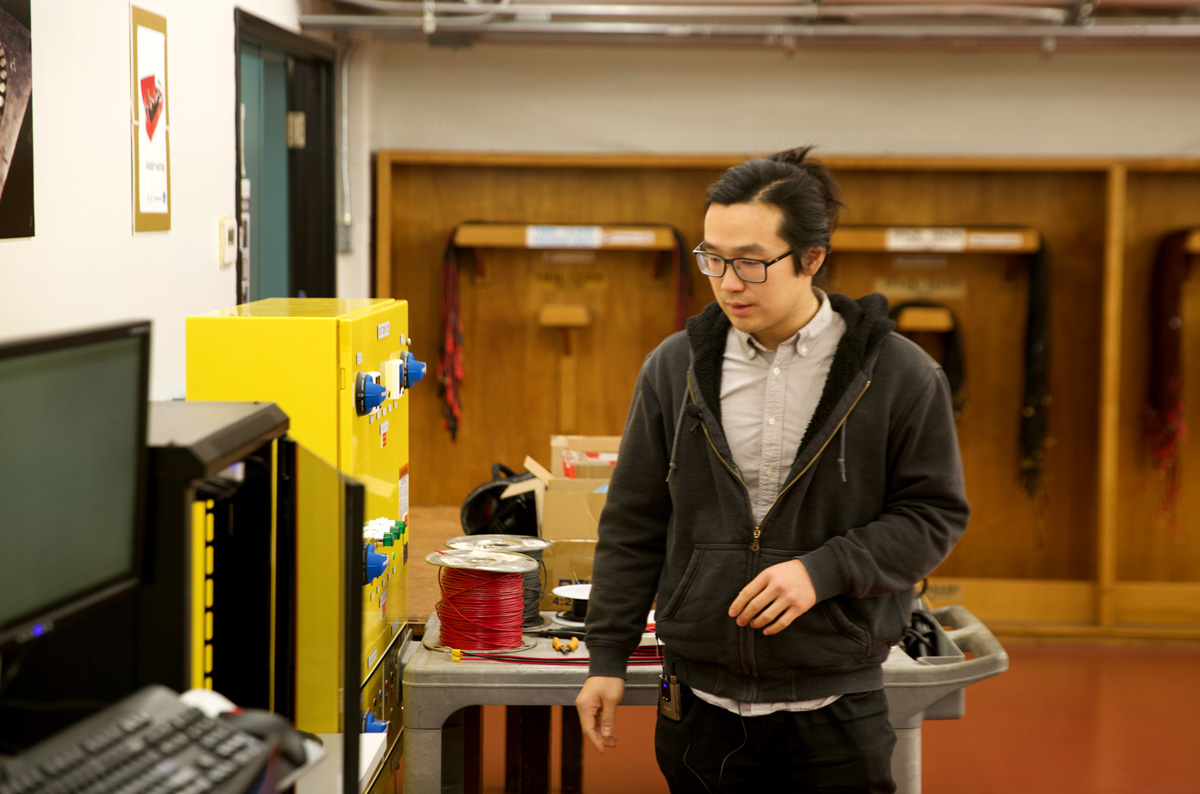

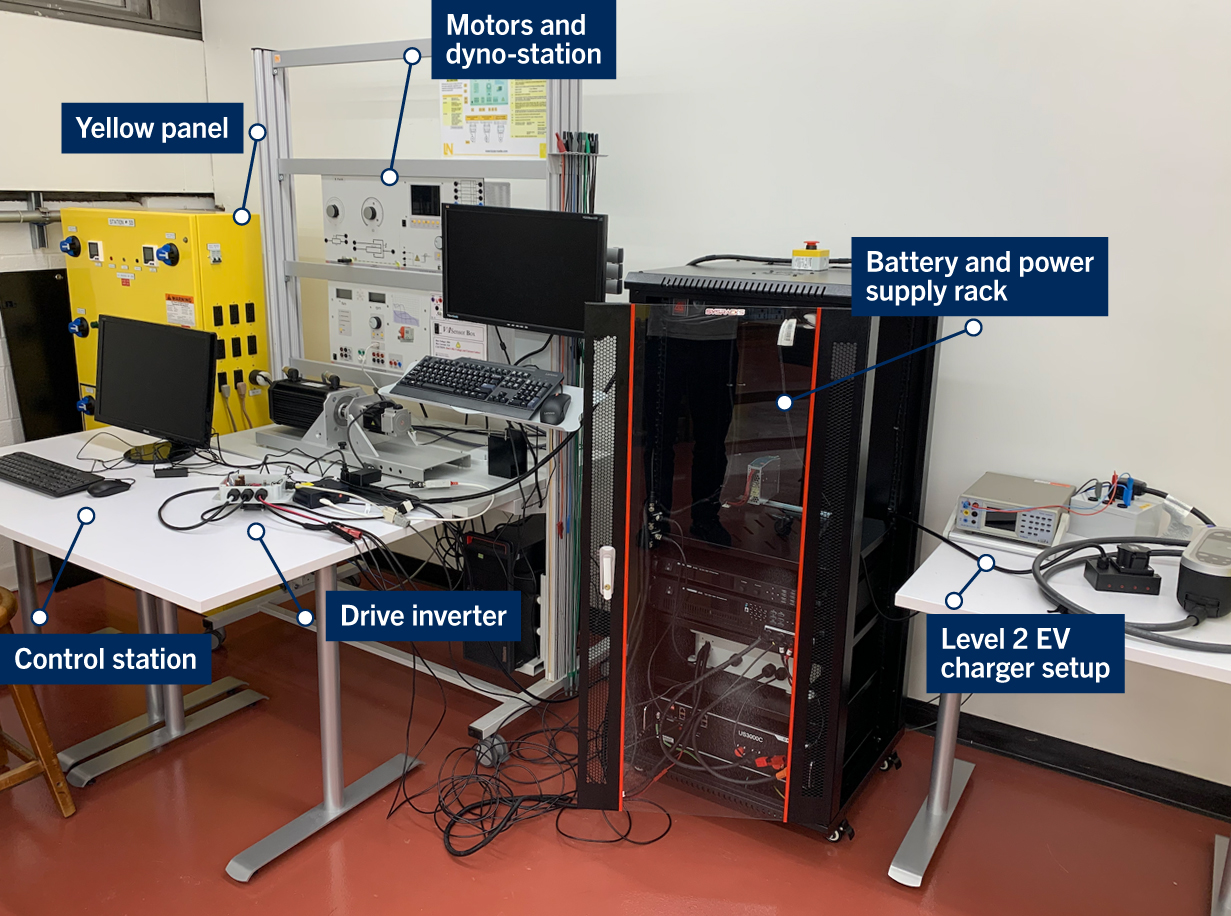

Gong says that the lab setup, situated in the ECE undergraduate Energy Systems Lab, took six months to develop, and leveraged several years of research from the University of Toronto Electric Vehicle (UTEV) Research Centre into the hardware and software requirements. EV working components are arranged on lab tables to provide full access, “as if a bench-top electric vehicle,” says Gong.

The setup includes a dynamometer that simulates how the road applies loading force to the vehicle propulsion system, a lithium-ion battery, hardware switches to selectively connect the battery to motor and charger, and a power supply to act as the on-board charger.

“We also have something that’s quite unique for an EV lab — EV supply equipment, something you would actually see in a home,” says Gong, pointing to a charger nozzle. “We customized the connection between our charger and power distribution panel to allow students to step through the communications interface required for the vehicle to engage the charging sequence.”

“Over the years, a lot of the equipment in the Energy Systems Lab has been designed by profs, research associates, grads, as well as undergrad students,” says Afshin Poraria, Director of Teaching Labs, describing the collaborative approach between faculty members, UTEV and undergrad lab managers in creating the lab setup.

“We build whatever we can to feed and expand the student experience. Before long, we’ll likely have undergrad students using this equipment,” he adds.

UTEV Director and ECE professor Olivier Trescases says that the “all hands on deck” approach and the creative solutions to equipping the labs are necessary to provide the best possible learning environment for students.

“Over the past few decades, ECE has made major investments to design and deploy custom infrastructure to deliver a unique training experience that is simply not possible with off-the-shelf equipment.”

“In ECE, our objective is to prepare our students to be innovation leaders to meet society’s needs,” says Professor Deepa Kundur, Chair of ECE. “This is especially the case when it comes to sustainability, and a new course offering in electric vehicles helps build a robust talent pipeline to provide the electrification industry with people ready to make a difference."

Gong, having been at ECE for all three of his degrees, is happy to play his part.

“Through my undergrad days to now, I’ve always known ECE’s labs to be collaborative ones. It’s very exciting for me to be contributing to a new stage, building custom equipment and now teaching the students about electric vehicles, something that I’m passionate about. It’s like coming full circle.”