MARCH 3, 2022 • By Matthew Tierney

As a kid, ECE Professor Sean Hum loved taking electronic devices apart to see how they worked. In time, he was able to create his own electronic circuits. Now he’s launched a new course that aims to introduce that hands-on experience to second-year ECE students.

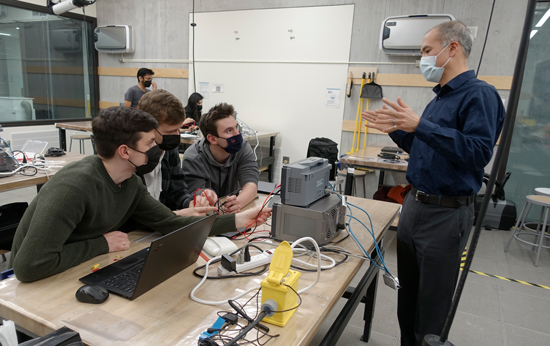

“When you walk into our space, it looks almost like a machine shop: prototyping equipment, 3D printers, power tools strewn about,” says Hum, adding that the lab features brand-new test instrumentation, soldering and surface-mount rework stations, a reflow oven, and cabinet after cabinet of electronic components. “For some people, it’s like being let loose in a candy store.”

The course, titled ECE 295: Hardware Design and Communication, made its debut in January. Hum originally conceived the idea two years ago to introduce students to milestone-driven hardware design — what he calls the ‘nuts and bolts’ of electrical and computer engineering — early in their learning curve.

“Having second-year teams design something from scratch,” Hum says, “where they are involved from the conceptual and computer-aided design right down to the mounting of components on the circuit boards — as well as using a variety of modern test and measurement equipment and debugging their designs — that end-to-end experience isn’t available at other universities, not at the second-year level.”

Hum adds that the teams design complementary modules that must work together in the end, which is “a unique aspect of this course that teaches students about system integration.”

This pedagogical structure reflects the course’s focus on context to strengthen the electrical engineering fundamentals that students gained in their first four semesters. Acquiring sophisticated physical techniques while working towards a user-centred product quickly solidifies those concepts.

It’s also a lot of fun.

“As human beings, our minds are wired to get satisfaction doing something physical with our hands,” says Hum. “I believe it’s one of the reasons for the rise of DIY or maker culture in society. People just love building things.”

The course is held in the Myhal Fabrication Facility, colloquially known as the ‘Myhal Maker Space.’ This state-of-the-art workshop is open 12 hours a day, five days a week to any student who passes the safety training, enabling them to turn ideas into prototypes when inspiration strikes. The new course, along with the high-end equipment and components to support it, is made possible in part by the Dean’s Strategic Fund.

ECE Chair Professor Deepa Kundur is pleased at how ECE 295 amplifies the core curriculum in balance with the existing second-year software design course.

“Experiential learning emboldens students to pursue hardware projects in future courses, such as our fourth-year Capstone course,” she says. “Ultimately, the department needs to be responsive to trends in the profession, and we’re hearing from our industry partners that there’s great demand for this skill set.”

Hum also sees the course as a complement to software design. He says that while new apps often garner the media attention, the industry needs engineers who are conversant in both the hardware and software, which are virtually inseparable in today’s appliances and products.

For example, while cars and washing machines once belonged exclusively to the world of hardware, today they contain an amount of software that would surprise most people. Conversely, many features of today’s mobile apps are only made possible by the hardware packed onto the smartphone’s motherboard, including nearly a dozen types of antennas.

“You have voice service and data service, you have positioning service through GNSS, you have WiFi, Bluetooth, near-field communications,” says Hum. “All of those require different radios. That’s why companies such as Apple are hiring so many antenna engineers.”

Hum’s own career path in electrical engineering owes much to his early obsession. He started tinkering with electronic devices in elementary school, and by high school he was designing radio circuits — with one eye on the stars.

“I was fascinated by space technology, and have special memories of Sojourner, the first Mars Rover mission in 1997,” he says. “It was amazing to me how we could pick up such weak signals from this tiny rover moving around so far away.”

These days, his research group develops antenna solutions based on advanced electromagnetic surfaces, in collaboration with aerospace firms. His experimentally focused research mirrors the same hands-on approach he takes with ECE 295, and the graduate students in his group learn about building actual flight hardware in the lab.

“We’re in a golden age for makers,” says Hum, “which is good news for electrical engineers. When the naturally curious are given the proper resources and guidance, the sky’s the limit.”

For more information:

Jessica MacInnis

External Relations Manager

The Edward S. Rogers Sr. Department of Electrical & Computer Engineering

416-978-7997 | jessica.macinnis@utoronto.ca